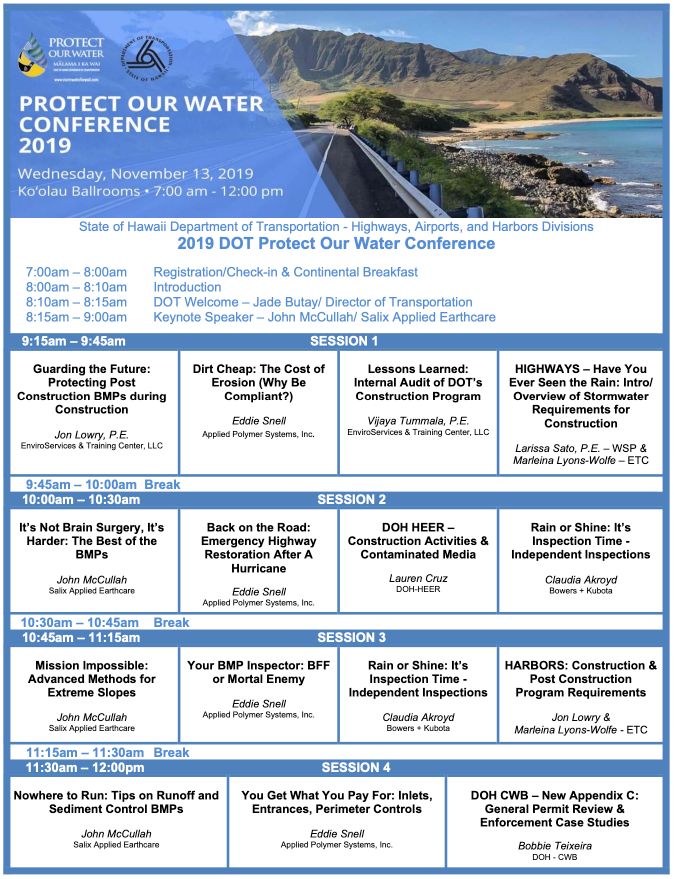

Posted at 16:13h

in

Archive,

Featured

The “Big Four” Erosion Control (raindrop) BMPs

I often inform my students that an estimated 90% of the erosion in the world is caused by raindrop erosion. You know, the energy from a falling raindrop onto bare soil is like a bomb!! Or actually millions of little bombs during a decent storm. It is this energy (Raindrop Impact) that detaches and dislodges soil particles, by a magnitude, at least, over tractive forces of flowing water erosion (Rills, Channel Bank, Bed, and Gully Erosion) My physics professor in college demonstrated that the raindrop, average size 1cm3, shaped to minimize friction, need only fall about 30-ft to reach maximum velocity. That raindrop erosion energy causes the first detachment and breakup of soil particles, and now that soil surface ready now for transport and delivery from sheet flow (sheet erosion). Note that Sheet Flow doesn’t have much excess energy to needed to dislodge – for that the energy comes from raindrop impact energy.

Envision Junior raindrop hitting bare soil and causing the explosion all the while it also hurts his tush. Junior will then get a bad attitude and begin running off! That is how rills start. That is why, in practicing good erosion control, we are being like good parents and not letting Junior get going too fast. Junior loves it when we leave the soil surface smooth and hard. But “good parents” will slow Junior down by roughening the soil surface and putting slope interrupters, like fiber rolls down across the slope/

Go to Jr raindrop Blog

Now envision Junior landing on grass or nice soft Mulch, making a cushion for his tush. He can then slowly infiltrate into the soil. Remember the axiom; “Less runoff from a site correlates to less discharge and less discharge greatly reduces the likelihood of receiving a regulatory action!”

The prerequisite for Raindrop Impact Erosion is laying the soil bare by removing the soil cover. This is usually an anthropogenic (human-caused) land-use problem. Therefore one of the MOST effective BMP is what I call the ‘thinking persons” BMP, which is a do-nothing BMP. That BMP is a “practice” and it is to, whenever possible, Reduce the Amount of Disturbed Area During the Rainy Season. This BMP is related to “Minimize Disturbance BMP” and that is “Leave a Vegetative Buffer BMP”. If a regulator or plan reviewer asks “Where are your Silt Fences”, I like to be able to reply – “See I have designated a Vegetative Buffer capable hydraulically to …..”

Back to the Raindrop Erosion

Let’s combine the assertion that 90% of the erosion in the world is caused by raindrop erosion with the fact that our “industry” has 4 (four) types of BMPs that are better than 90% effective in reducing Raindrop Impact Erosion. Stated another way, we currently have the Best Available Technology (BAT) that could reduce 90% of the erosion in the world, and that especially includes construction sites. Let’s note these are BMPs that are widely used, tested, and non-vegetative in that they are BMPs that are immediately effective upon application.

Can you guess what the BMPs are? Note I’m not including grasses, seeding or other types of vegetation because even grass seeding takes 3-weeks or more to get protective cover.

The four commonly used BMPs, I call them the “Big Four”, are; 1.) Straw Mulch (94% effective), 2.) Rolled Erosion Control Products (RECPs) (92% – 96% effective), 3.) BFM Hydromulch (some products are 95% – 98% effective, and 4.) Compost Blanket (the uniform coverage of soil with STA Certified Compost, 1.5-inch to 2-inch thick covering, on up to 1:1 slopes**.

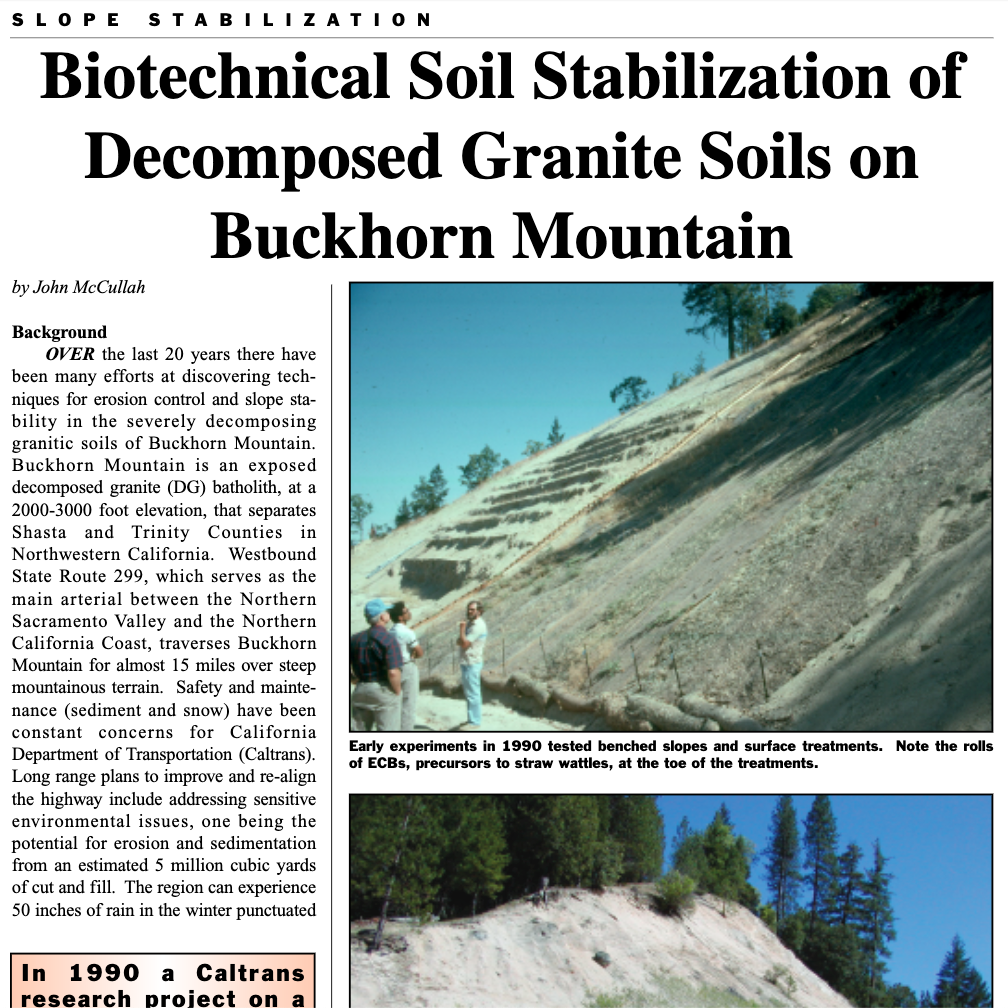

Generally, the “Big Four” are recommended for slopes approximating 2:1 but the can be and are occasionally used successfully on steep slopes (up to 1:1 or steeper). However, design considerations are even more important.

In 2010 Caltrans Department of Landscape Architecture developed guidance for steep slopes, see this link for more information:

https://dot.ca.gov/programs/design/lap-erosion-control-design/tool-1-lap-erosion-control-toolbox

Direct Run-on Away From Slope: To successfully implement erosion control (the Big Four) on slopes all concentrated runoff must first be directed off the slope – only raindrop erosion, please. The Junior Raindrop video taught us the difference between raindrop erosion (hurting Junior’s ‘tush’ as he dislodges particles) versus the tractive forces erosion when Junior and his gang start running. Two entirely different physical processes are involved, gravity and the falling raindrop, vs. kinetic energy – and shear and tractive forces of flowing water.

Selection Criteria for the “Big Four”

1. Straw Mulch: SM is generally restricted to 2:1 slopes and the ability to anchor the straw effectively with a strong tackifier. Generally, the 2:1 slope should be groomed uniformly and roughened. For the tack coat, I like to use wood fiber hydromulch @ 700# /ac and Guar @ 100-120 # /acre for steep slope applications of Straw Mulch @ 1.5-2.0 T/ac. See the BMP Manual and “Straw Talk”. https://youtu.be/m91AWMLeAoU

2. Erosion Control Blankets (ECB) and Mats: The primary prerequisite to selecting Rolled Erosion Control Products is the ability to grade the slope uniformly (not slick and compacted) to allow “intimate soil contact” and you will be limited by your ability to anchor the ECB with pins. If your slope is excessively rocky and/or there are stumps and clods then you may want to select an equally effective BMP, such as Hydromulch BFM, that doesn’t require anchor pins. Also putting laborers on steep slopes can be challenging. Both BFM (applied hydraulically) and Compost Blanket (applied pneumatically with blower truck) are worthy of considering for steep slopes**.

Always seed the slope before placing the ECB. Some practitioners will Hydroseed the slope before mat installation but hand seeding is also acceptable, be careful, don’t allow workers to disturb seed much while anchoring ECB.

Another criteria for selecting an appropriate ECB is durability and how fast it will degrade. The ECB chosen should not degrade before the vegetative cover can become established. For example, in New Mexico, the DOT determined it took about 3-years for the “native grass/sage regime” to become established. Therefore only Coir Blankets or Excelsior Blankets had the durability to provide the protection needed until the natives took over.

3. Hydromulch BFM: In my experience, and the research bears this out, it takes a BFM Hydromulch to perform in the 96% effective range. The fiber type is important when selecting a BFM, with virgin wood fiber having the most internal friction and tensile strength. But the most important component of an effective BFM is the tackifier(s) that are used – guar and a thermally altered derivative of guar. Yes, the secret sauce recipe is finally been revealed!

BFM, to be 96% effective must be applied for 100% coverage at a rate of 4000 lbs./acre. FYI, one cannot achieve 100% cover over 1 ac of bare soil with 3500 lbs./ac. Also note, if you surface roughen the soil before Hydromulching (preferred practice) you will inadvertently increase the surface area of the soil. It is estimated that dozer tracking a slope will increase the soil surface area by approximately 30%. One can see that BFM applied at 4000#/ac as a minimum is necessary for 100% coverage. Question, How many bags should the Contractor show up with to apply BFM at 4000#/ac? BFM and all hydromulches come in 50# bags. How many bags will it take if you also plan on Track Walking?

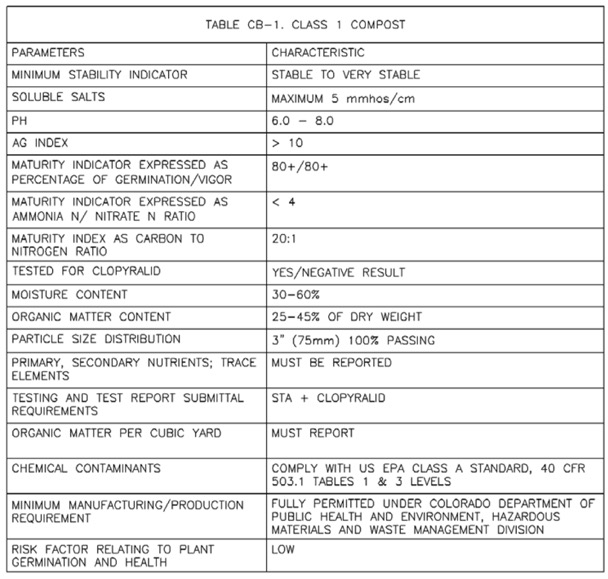

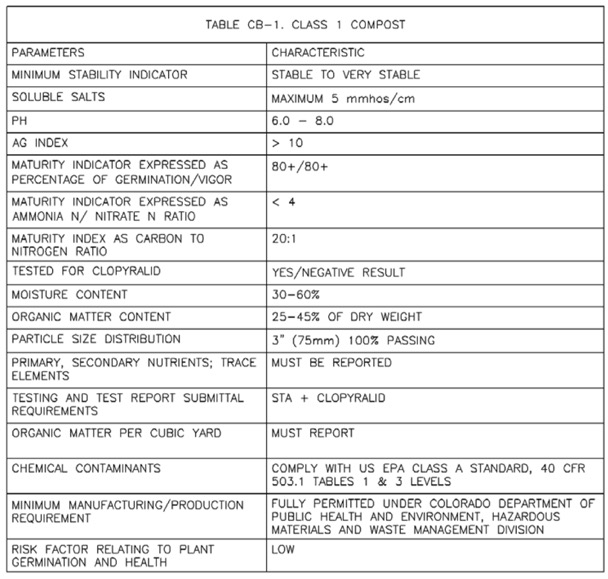

4. Compost Blankets: First of all, Compost Blankets as a BMP is defined as a blanket of compost placed over the soil surface at specified thickness AND the Compost must the STA Certified Compost

https://dot.ca.gov/programs/design/lap-erosion-control-design/tool-1-lap-erosion-control-toolbox/tool-1k-11-compost

Before compost application, “the Contractor shall provide the Engineer with a copy of the compost producer’s Compost Technical Data Sheet and a copy of the compost producers STA certification. The Compost Technical Data Sheet shall include laboratory analytical test results, directions for product use, and a list of product ingredients.”

Here is an example of the STA Compost Test Certificate from Colorado.